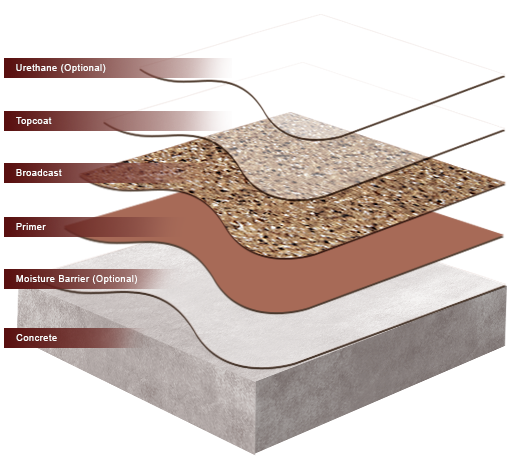

Epoxy Coating Process

Step 1: Diamond Grind/Shot Blast

We create a profile for mechanical adhesion to ensure a great bond between the concrete and base coat. Grinding or shot blasting will remove any oil, grease, dirt, mildew, form release agents, curing compounds, loose and flaking paint, etc., leaving a porous substrate for the primer to penetrate. New concrete still needs to go through this step.

Step 2: Clean Floor

We will clean the surface to remove any dust and debris from the area at this time.

Step 3: Perform All Floor Repairs

If there are any cracks, divots, or other surface imperfections, repairs will be performed at this point to provide a good foundation for a long-lasting, high-quality finished product.

Step 4: Apply Moisture Vapor Barrier

This coating is a specialized epoxy-based barrier that inhibits the passage of moisture, which can be present in the concrete due to factors like high humidity, ground moisture, or water vapor transmission.

Step 5: Apply Penetrating Base Coat

An epoxy primer has a better bond than traditional primer. It wicks into the porous concrete to achieve a strong hold between the surface and epoxy floor system.

Step 6: Broadcast To Rejection

We evenly spreading material over the epoxy base coat to achieve full coverage. Glass City Coatings offers different designs and textures using materials such as sand, flakes, ceramic quartz, etc. A second broadcast can be added to the floor system for maximum durability.

Step 7: Topcoat

A low VOC epoxy topcoat is applied to add a thick layer of protection for the broadcast material.

Optional: U.V. stable urethane topcoat is available to apply over the epoxy layer to increase abrasion resistance for a more sustainable floor.

Step 8: Return To Service

Application requirements will determine return to service timing. Our goal is to make your surface ready for everyday use as soon as possible.

Polished Concrete & Terrazzo Restoration Process

In order to produce beautiful and durable polished concrete floors or restore terrazzo floors, we diamond grind, add a floor hardening agent, polish and buff the floor. This process is extensive and requires professionals for great and reliable results. Glass City Coating would be happy to discuss the process of polished concrete as a flooring option for your facility or how we can restore your terrazzo floors.